HOW-TO GUIDES

The Essential Guide to Asphalt Maintenance for Long-Lasting Pavements

Overview of Asphalt Maintenance

Due to its strength and flexibility, asphalt remains a preferred choice for constructing driveways, roads and parking lots. Nevertheless, like any material exposed to the elements, it demands regular attention to maintain its robustness and appeal. Simple routine actions such as sweeping away debris and swiftly sealing any emerging cracks, can significantly influence the lifespan and appearance of an asphalt surface. Those considering enhancements or refurbishments seeking on-site paving estimates Granger, IN, can provide tailored solutions that ensure the durability and aesthetics of their surfaces.

Many might wonder why asphalt needs such attentive care. The absence of a proactive maintenance routine can lead to rapid degradation. Beyond just marring appearance, surface deformations can create hazards for pedestrians and vehicles alike. By undertaking regular maintenance, one can avoid the pitfalls of neglect which often result in expensive, large-scale repairs. Model preventative measures assure both longevity and safety for asphalt installations.

Why Pavement Maintenance Matters

The cornerstone of sustainable infrastructure lies in its maintenance. Pavement upkeep enhances longevity and significantly reduces the risks associated with everyday wear and tear. Minor untreated issues can quickly snowball into significant structural damages, demanding costly interventions. As a detailed analysis showcases, methodical and consistent maintenance regimes have helped cities save substantially on repair costs. The economic advantages are a strong impetus for businesses and municipalities to engage in routine pavement care.

Maintenance extends benefits beyond just cost savings. It enhances vehicular and pedestrian traffic safety and can uplift the visual appeal of urban and suburban spaces. For property owners, this translates to higher property value and increased satisfaction among tenants and visitors. Therefore, understanding and implementing a thorough maintenance strategy becomes indispensable in urban planning and property management.

Common Asphalt Issues and Solutions

Asphalt surfaces are subjected to continuous pressure from traffic and natural forces, leading to various problems. The most common issues include cracking, potholes, and drainage inefficiencies. If neglected, cracks let water seep into the pavement base, weakening the structure. Potholes form when water expands in these gaps during freeze-thaw cycles, causing further deterioration. Addressing these promptly with targeted solutions like crack filling and patching curtails further damage and extends the pavement’s lifespan.

Choosing the appropriate materials and repair techniques is essential. For example, using high-quality sealants can help extend the life of repair work, contributing to a seamless, durable finish. Property managers may maintain the effectiveness and efficiency of their maintenance schedules by staying current on the most recent developments in repair technologies.

Proactive Maintenance Techniques

Proactive measures prevent damage before it starts, which is valuable in asphalt maintenance. Techniques such as seal coating create a barrier against moisture and chemicals, offering a shield against premature wear. Likewise, efficient drainage systems are pivotal in directing water away and minimizing water-related damage. According to insights from the Federal Highway Administration (FHWA), proactive maintenance can reduce pavement lifecycle costs while maintaining performance standards.

Strategic planning and savvy investment in suitable materials lead to long-term benefits. Property owners can tailor their maintenance practices to fit specific needs by understanding seasonal variations and environmental challenges, resulting in profound savings and heightened pavement performance.

Importance of Regular Inspections

Inspections serve as the first line of defense against deterioration. Periodic assessments help identify signs of distress, such as subtle cracks or slight depressions. Instituting a regular inspection protocol allows decision-makers to prioritize maintenance tasks, efficiently allocating resources where they are most needed. This foresight not only prevents potential hazards but also optimizes budget expenditure.

By maintaining detailed records of inspections, property managers can identify patterns of wear and adapt their maintenance strategies accordingly. This comprehensive, data-driven approach aids in predicting future problems, enabling a proactive stance on maintenance.

Cost-Effective Maintenance Alternatives

With budgetary constraints prevalent, exploring cost-effective maintenance solutions becomes vital. Recycling asphalt for reuse is among the most promising avenues, allowing for both environmental and fiscal benefits. By reclaiming existing materials, owners can reduce waste and cut expenditures associated with sourcing new materials.

Opting for local resources minimizes transportation costs, enhancing projects’ economic viability. Adopting such practices benefits the bottom line and aligns with broader sustainability goals.

Environmental Considerations in Asphalt Care

The demand for environmentally conscious infrastructure solutions is escalating. Sustainable practices in asphalt maintenance are not just ecologically sound but are increasingly becoming regulatory necessities. Green technologies like porous asphalt allow for better stormwater management and improve pavements’ aesthetic and functional quality.

Property managers can create lasting value by focusing on sustainability while playing an essential role in preserving natural resources for future generations. Leading by example in adopting sustainable practices can inspire broader ecological responsibility, transforming industry standards.

HOW-TO GUIDES

Shop Smart and Save with Goldengatemax.shop Online Guide

In today’s fast-paced world, online shopping has become a staple for many. From the comfort of our homes, we can access countless products and deals, all at the click of a button. But with this convenience comes the challenge of navigating the vast sea of options available. If you’re wondering how to make the most of your online shopping experience, you’re in the right place. Welcome to Goldengatemax.shop, where we guide you to the best online shopping experience, helping you uncover incredible deals while ensuring a smooth and satisfying purchase process.

Understanding the Online Shopping Landscape

The online shopping landscape is a dynamic and constantly evolving space. It’s a marketplace that’s not bound by geographical limitations, offering consumers access to a wide variety of products from around the globe. Understanding this landscape is crucial for any savvy shopper. It helps to know where to look, what to look for, and how to discern quality from gimmicks.

The rise of e-commerce giants like Amazon and niche market platforms have revolutionized how we shop. These platforms offer everything from groceries to luxury goods. However, with this extensive range comes the responsibility of sifting through options to find the best deals and highest quality products. This is where Goldengatemax.shop shines by providing a curated selection of items, ensuring you don’t get lost in the endless options available online.

Navigating Goldengatemax.shop

Goldengatemax.shop is designed to be user-friendly and intuitive. The first thing you’ll notice is the easy-to-navigate categories that allow you to find exactly what you’re looking for quickly. Whether you’re searching for electronics, fashion, or home goods, our organized layout ensures a seamless shopping experience.

Once you’ve selected a category, you’ll find detailed product descriptions and user reviews that provide insights into the quality and performance of each item. This transparency empowers you to make informed purchasing decisions. Additionally, our search function is optimized to help you filter results based on your preferences, such as price range, brand, and customer ratings.

The Advantages of Shopping with Goldengatemax.shop

Shopping with Goldengatemax.shop offers numerous benefits that enhance your online shopping experience. One of the primary advantages is the variety of bean selections we offer. Each product is carefully selected and vetted to ensure that you receive only the best options available, catering to diverse tastes and preferences.

Another advantage is our expert curation. Our team of specialists ensures that every product listed meets high standards of quality and value. This curation process saves you time and effort, allowing you to enjoy a hassle-free shopping experience. With Goldengatemax.shop, you can trust that you’re getting the best products without having to wade through countless options.

Exclusive Deals and Offers

At Goldengatemax.shop, we believe that great deals should be accessible to everyone. That’s why we offer exclusive deals and discounts to our subscribers. By signing up for our newsletter, you’ll receive regular updates on the latest promotions and special offers, allowing you to save on your favorite products.

These exclusive deals are tailored to suit a variety of preferences and needs, ensuring that there’s something for everyone. From seasonal sales to limited-time discounts, our offers are designed to enhance your shopping experience and provide exceptional value.

Building a Community of Shoppers

Goldengatemax.shop is more than just an online store; it’s a community of passionate shoppers who share a love for discovering great products and deals. By joining our community, you’ll have access to a wealth of knowledge and resources shared by fellow shoppers.

Our platform encourages interaction and engagement, allowing you to connect with other shoppers, exchange tips, and share experiences. This sense of community adds an extra layer of enjoyment to your shopping experience, making it more than just a transaction.

Tasting Notes Included with Each Purchase

When you make a purchase on Goldengatemax.shop, you’re not just buying a product; you’re embarking on a sensory adventure. For our coffee enthusiasts, each shipment comes with detailed tasting notes that explore the flavors and aromas of the beans. This enhances your appreciation of the product and allows you to enjoy a richer, more informed experience.

These tasting notes are curated by experts who understand the nuances of flavor profiles. They provide insights into the origins of the beans and suggestions on how to best enjoy them, ensuring that every cup is a delightful experience.

How to Make the Most of Your Shopping Experience

To get the most out of your shopping experience with Goldengatemax.shop, consider these practical tips. Firstly, take advantage of our search and filter options. By refining your searches, you can easily narrow down your options and find exactly what you’re looking for.

Secondly, make use of the customer reviews and ratings available on our platform. These reviews provide valuable insights and firsthand experiences, helping you make informed decisions. Additionally, don’t hesitate to reach out to our customer support team if you have any questions or need assistance.

Staying Safe While Shopping Online

While online shopping offers convenience, it’s important to prioritize safety and security. At Goldengatemax.shop, we take your privacy seriously and implement robust security measures to protect your information. Always ensure that you’re shopping on a secure connection and never share sensitive information unnecessarily.

It’s also a good idea to regularly review your account activity and set strong passwords to safeguard your account. By staying vigilant, you can enjoy a worry-free shopping experience on our platform.

The Future of Online Shopping with Goldengatemax.shop

The future of online shopping is bright, and Goldengatemax.shop is at the forefront of this exciting evolution. We continuously strive to enhance our platform and services, ensuring that we meet the changing needs of our customers.

Looking ahead, we plan to expand our product offerings and introduce new features that make shopping even more enjoyable and convenient. Stay tuned for exciting updates as we continue to innovate and redefine the online shopping experience.

Conclusion

Goldengatemax.shop is your go-to destination for an exceptional online shopping experience. With our user-friendly platform, expertly curated products, exclusive deals, and a vibrant community, we offer everything you need to shop smart and save.

Join us today and discover the joys of online shopping with Goldengatemax.shop. Whether you’re a seasoned online shopper or new to the experience, we’re here to provide you with the best deals, the finest products, and an unparalleled shopping adventure. Visit us now and start your shopping journey with confidence!

HOW-TO GUIDES

Mastering Fusion 360 for 3D Printing Secrets to Success

In the world of 3D printing, having the right design tools can make all the difference. Fusion 360 stands out as an indispensable ally for designers crafting intricate models ready for the 3D printer. Whether you’re a hobbyist, a professional designer, or someone curious about getting started, understanding the basics and tips of Fusion 360 is essential. This blog post will guide you through the nuances of mastering Fusion 360, ensuring your creations come to life just as you imagined.

Fusion 360 is more than just a modeling tool; it’s a comprehensive platform that offers everything from sketching to rendering. Its versatility makes it a favorite among users who want to bring their ideas from concept to reality efficiently. By jumping into Fusion 360, you’re tapping into a tool that can streamline your design process and help you create more precise, intricate models.

Throughout this guide, we’ll explore various aspects of Fusion 360, offering practical tips and insights that will make your 3D printing projects successful. From understanding the interface to advanced modeling techniques, this tutorial will equip you with the knowledge to harness the full potential of Fusion 360.

Understanding the Fusion 360 Interface

Navigating any new software can be daunting, but Fusion 360’s interface is designed to be user-friendly once you get the hang of it. Let’s break down the essential components.

At the core of Fusion 360 is its intuitive toolbar, where you’ll find all the tools necessary for sketching, modeling, and rendering. Familiarizing yourself with this toolbar is your first step in becoming proficient with the software. Each tool has a specific function, and understanding these will significantly improve your design efficiency.

The browser panel, located on the left side, is another crucial area to understand. Here, you manage your components and sketches. Think of it as the backbone of your project organization; keeping it tidy will save you headaches down the line. Spend some time exploring how to use this feature to keep your projects structured.

Lastly, the canvas is where your creativity comes to life. This is your design space, where you’ll sketch and model your ideas. Knowing how to manipulate views and utilize the navigation tools will make your experience smoother and more productive. Practice rotating and zooming in the canvas to gain confidence in your movements.

Starting with Sketches

Before a model becomes a tangible product, it begins as a simple sketch. Sketching in Fusion 360 is the foundation of your design process.

Start by selecting the “Create Sketch” tool from the toolbar. This initiates a new sketch plane, where you can draw the basic shapes that form the basis of your model. Consider sketching as laying the groundwork for your design; precision here will pay off later.

Utilize constraints to ensure your sketches are accurate. Constraints help maintain relationships between different sketch elements, such as parallel lines or fixed distances. Applying these correctly means your model will behave predictably as you develop it further.

Dimensioning is another critical aspect of sketching. By setting dimensions, you ensure your sketches have the exact measurements needed for your model. This step is vital for creating scaled models suitable for 3D printing, so don’t skip over it!

Extruding and Revolving

Once your sketch is ready, it’s time to bring it into the third dimension. Extruding and revolving are two primary methods to turn sketches into 3D models.

Extrusion involves extending a 2D sketch along a straight path to add depth. This technique is perfect for creating simple, linear objects. To extrude in Fusion 360, select the sketch, choose “Extrude” from the toolbar, and specify the distance. Voila! Your sketch morphs into a three-dimensional object.

Revolving, on the other hand, is used for creating symmetrical objects around an axis. Imagine designing a vase or a wheel; revolving creates these types of shapes effortlessly. In Fusion 360, you select your sketch, pick the axis, and then revolve the sketch to see it take form.

Both methods are integral in your design toolkit. Practice using them to grasp how they can dramatically transform your sketches into complex models quickly.

Advanced Modeling Techniques

Basic extrusion and revolving are just the beginning. Fusion 360 offers advanced modeling techniques that allow you to create even more complex designs.

Lofting is one such technique. It lets you connect multiple profiles to form a smooth transition between shapes. For instance, imagine creating a bottle; lofting enables you to seamlessly blend the neck into the body of the bottle. Select your profiles, click “Loft,” and watch as Fusion 360 does the hard work.

Filleting and chamfering are essential for adding finishing touches. These tools help you round edges or create beveled transitions, adding a professional touch to your model. Use them to refine your model’s edges, improving both aesthetics and functionality.

Another powerful tool is the pattern feature, which allows you to duplicate features across a model. Whether it’s a series of holes or repeating structural elements, patterns save time and ensure precision. Investigate linear, circular, and rectangular patterns to see how they fit into your design process.

Preparing for 3D Printing

Once your model is complete, preparing it for 3D printing is the next crucial step. Fusion 360 simplifies this process with its built-in tools.

Firstly, ensure your model is watertight. This means there are no gaps or holes that could lead to printing issues. Use the “Inspect” tool to check for errors and make corrections as needed to ensure print readiness.

Next, orient your model correctly. The orientation can affect the strength and appearance of the final print. Position your model in a way that minimizes the need for supports, which can be removed but often leave marks.

Finally, export your model in the correct file format. STL and OBJ are the most common formats for 3D printing. Fusion 360 allows you to export these formats easily, ensuring compatibility with your 3D printer software.

Tasting the Fusion 360 Community

Beyond the technical aspects, being part of the Fusion 360 community can enhance your learning and application of the software.

Join forums and groups where users share tips and solutions. This network of fellow designers can provide support and inspiration, helping you overcome challenges and discover new techniques. Engaging with others will broaden your understanding and introduce you to diverse perspectives.

Participate in challenges and contests. Autodesk frequently hosts design challenges that encourage creativity and innovation. These events are not only fun but also push you to apply what you’ve learned in new and exciting ways. Plus, they offer networking opportunities with like-minded individuals.

Sharing your own projects can also be rewarding. By posting your designs, you receive feedback and recognition. This interaction fosters growth and places you in the broader community of creators and innovators.

Common Mistakes and How to Avoid Them

Even with the best tools, mistakes can happen. Knowing common pitfalls in Fusion 360 and how to avoid them will set you up for success.

One frequent mistake is overlooking constraints in sketches. Without proper constraints, your model may not behave as expected during modifications. Always double-check that all necessary constraints are applied before transforming your sketch.

Another issue is working without layers. Organizing your design into layers or components helps manage complex projects. This organization makes it easier to identify and modify specific aspects of your model without affecting others.

Lastly, ensure you save your work regularly. Fusion 360 has an autosave feature, but taking control of your saves means nothing is lost if unexpected issues arise. Make it a habit to save before making significant changes.

Fusion 360 Tips for Beginners

Starting with Fusion 360 can be overwhelming, but these beginner tips will help you get off on the right foot.

Start with simple projects. Building confidence with simple designs allows you to learn the basics before tackling more complex projects. Focus on mastering fundamental tools and techniques first.

Explore tutorials and online resources. Numerous tutorials are available online, covering everything from basic sketching to advanced modeling. These resources can supplement your learning and provide additional insights into effective workflows.

Don’t hesitate to experiment. Fusion 360 is about exploration and creativity. Test different features and see what happens. Mistakes are part of the learning process and often lead to unexpected discoveries and improvements.

Enhancing Your Skills with Practice

Practice makes perfect, and the same applies to mastering Fusion 360. Regular practice will hone your skills and deepen your understanding of the software.

Set aside dedicated time for practice each week. Consistency is key to retaining what you’ve learned and building upon it. Schedule practice sessions just like you would any other important task in your calendar.

Work on diverse projects to challenge yourself. Trying new design styles and applications can expand your knowledge and adaptability. Each project you complete increases your proficiency and readiness for future challenges.

Reflect on completed projects to identify areas for improvement. Analyze what went well and what could be refined. This reflection encourages growth and prepares you for more complex endeavors in the future.

Leveraging Fusion 360 for Professional Growth

Proficiency in Fusion 360 can significantly benefit your professional development, whether you’re a hobbyist or aspire to work in design and engineering.

Adding Fusion 360 to your skill set enhances your resume and increases your marketability to potential employers. Many industries value expertise in this software for its versatility and capability in creating intricate designs.

Consider obtaining certification from Autodesk. Certification validates your skills and demonstrates your commitment to mastering Fusion 360. It’s a formal recognition of your abilities that can open doors to career advancement.

Networking with professionals who use Fusion 360 can also be advantageous. Building connections with industry experts can lead to collaborations or job opportunities. Sharing experiences and knowledge strengthens your position within the field.

Why Fusion 360 Is Ideal for 3D Printing

Fusion 360 is well-suited for 3D printing, and its features cater to the unique demands of this technology.

Its parametric modeling capabilities allow for precision and customization, which are crucial for successful 3D prints. You can easily adjust dimensions and parameters, making it ideal for iterative design processes.

The software’s integration with CAM (computer-aided manufacturing) streamlines the transition from design to production. This integration means your designs can move seamlessly into the manufacturing phase, saving time and reducing errors.

Fusion 360’s cloud-based platform offers flexibility and accessibility. You can access your projects from anywhere, collaborate with others, and ensure your designs are always up-to-date without the need for manual updates.

Conclusion Thriving with Fusion 360

By now, you should have a solid understanding of how Fusion 360 can transform your 3D printing projects. Mastering its basics and applying proven tips will empower you to bring your creative visions to life more effectively.

Remember, practice and community engagement are key to unlocking the full potential of Fusion 360. Continue experimenting, connecting with others, and expanding your skills to thrive in this exciting field.

For those eager to explore more, numerous online resources and tutorials are available to deepen your knowledge. Consider reaching out to fellow Fusion 360 users for support and collaboration. Together, we can push the boundaries of what’s possible with 3D printing and design.

-

BLOG1 year ago

BLOG1 year agoEscape to Tranquility Experience Grange Bardage Percheronne in Normandy

-

LIFESTYLE1 year ago

LIFESTYLE1 year agoAir Jordan 1 Retro High Off-White University Blue

-

SOCIAL MEDIA1 year ago

SOCIAL MEDIA1 year agoDecoding the Drive Social Media Pyramid Scheme Mystery

-

LIFESTYLE1 year ago

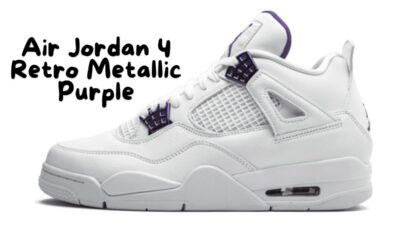

LIFESTYLE1 year agoAir Jordan 4 Retro Metallic Purple

-

BLOG9 months ago

BLOG9 months agoDecoding 540-315-8592: From Numbers to Messages

-

HOW-TO GUIDES1 year ago

HOW-TO GUIDES1 year agoShop Smart and Save with Goldengatemax.shop Online Guide

-

BUSINESS1 year ago

BUSINESS1 year agoDemystifying 315-442-5267 Common Myths and Facts Revealed

-

LIFESTYLE1 year ago

LIFESTYLE1 year agoAir Force 1 Shadow Pistachio Frost